Plate Type Heat Exchanger (PHE)

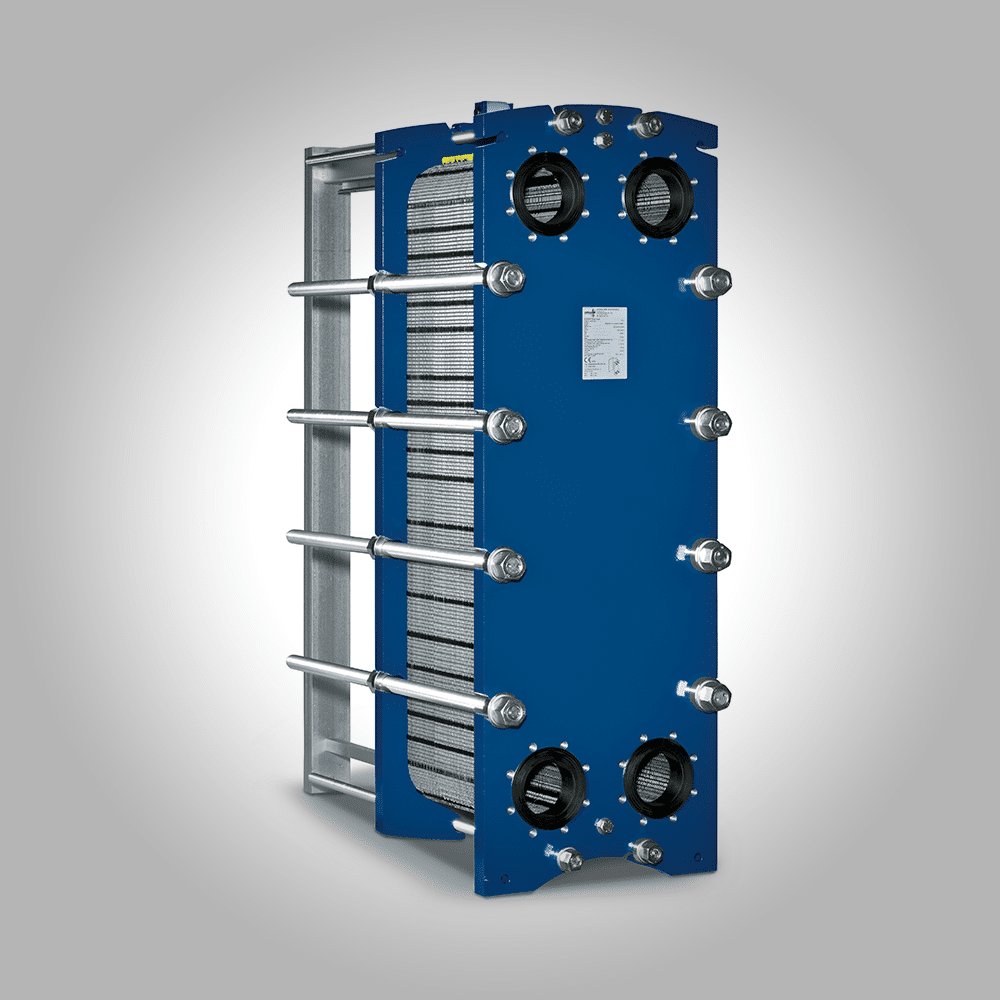

We provide the customized plate type heat exchanger for all your needs.

Plate Type Heat Exchanger. Heat Recovery System called Heat Exchanger and also Heat Transfer Recovery System Our Plate type and shell and tube type system saves energy of heat and cooling in the process of every industry. we have available customized plate type and shell and tube type heat transfer systems.

A plate heat exchanger uses a series of metal plates to move heat from one fluid to other. These plates are positioned over each other to create a channel’s series so that fluid can move between them. In the 1920s, Dr. Richard Seligman invented the plate heat exchanger (PHE).

The main benefit of the plate heat exchangers over conventional heat exchangers is that the fluid is distributed over the plate due to that fluid is exposed to a larger surface area. This increases the heat transfer rate and significantly speeds up the rate of temperature change.

Plate Type Heat Exchanger. Heat Recovery System called Heat Exchanger and also Heat Transfer Recovery System Our Plate type and shell and tube type system saves energy of heat and cooling in the process of every industry. we have available customized plate type and shell and tube type heat transfer systems.

The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

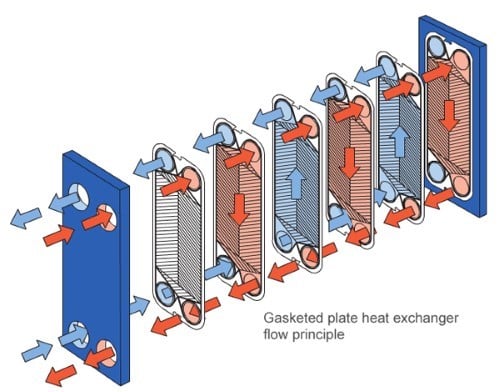

What is Gasket Type Heat Exchanger?

This heat exchanger uses top-quality gaskets and construction. This gasket seals the plates and stops leakage. You can easily remove the plates of this exchanger for the replacement, expansion, or cleaning of the plates, which significantly reduces maintenance costs.

Gasketed plate heat exchangers optimizes heat transfer. The corrugated plates provide easy heat transfer from one gas or liquid to the other.

How Gasket Type Heat Exchanger works?

Plates for a gasket plate heat exchanger are with elastomeric gaskets. These seal the channels and direct the mediums into alternate channels. The plate pack is between the frame plate and a pressure plate. It’s then compressed with bolts between the plates. The upper carrying bar supports the channel and pressure plate. They are then fixed in a position by a lower guiding bar on the support column. This design is easy to clean and modified (by removing or adding plates).

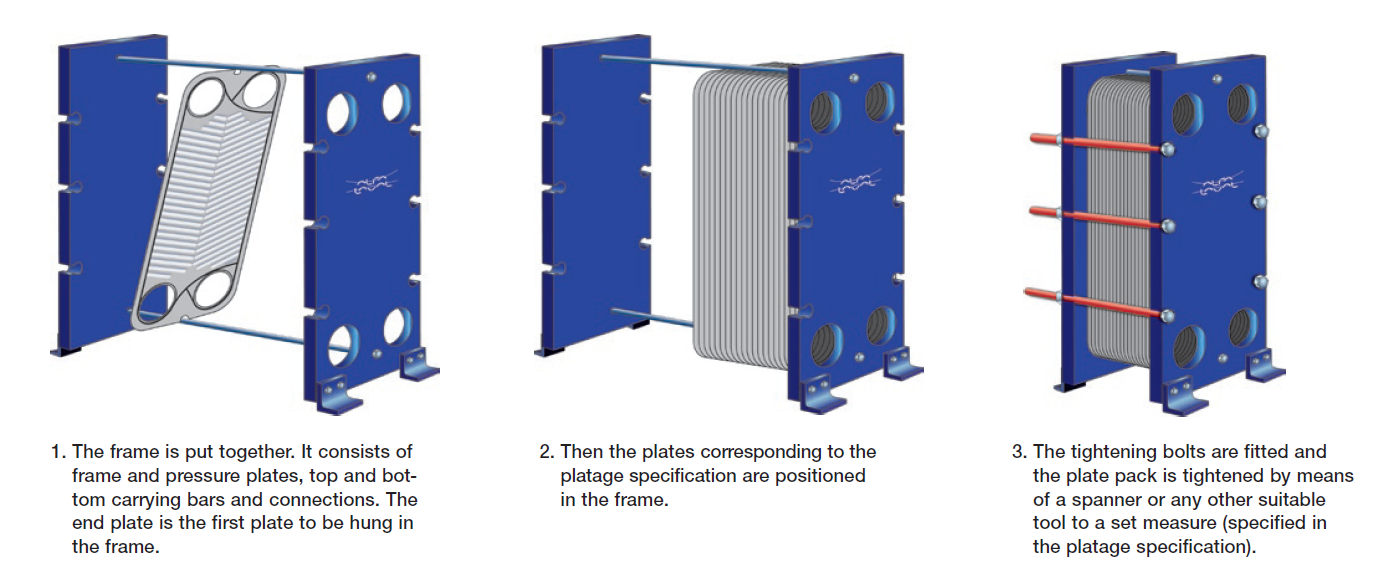

How to Assemble Gasket Type Heat Exchanger works?

Here are three steps to assemble a gasket plate heat exchanger:

Advantages of plate type heat exchanger:

- Heat transfer precision – improved temperature approach, true counter-current flow, 80-90% less hold-up volume.

- Low cost - low capital investment, installation costs, limited maintenance and operating costs.

- Greatest reliability - less fouling, stress, wear, and corrosion.

- Responsible - least energy consumption for most process effect, reduced cleaning.

- Easy to expand capacity – adjustable plates on existing frames.

Disadvantages of plate type heat exchangers:

- Poor sealing would cause leakage occurrence which will be a replacement hassle.

- Limited pressure use, generally not more than 1.5MPa.

- Limited operating temperature due to temperature resistance of the gasket material.

- Small flow path, and not suited for gas-to-gas heat exchange or steam condensation.

- High blockage occurrence especially with suspended solids in fluids.

Summary

We provide all types of plate type heat exchangers and gasket type heat exchangers for all your needs.

Get in touch with our support team. They will guide you as per your requirements.

PHE stands for PLate Type Heat Exchangers.

A plate heat exchanger is used to transfer heat energy from one fluid to another. These fluids never encounter each other due to being separated by the heat exchanger.

Plate Exchanger is the most efficient due to turbulent flow on both sides. High heat-transfer coefficient and high turbulence due to even flow distribution are important. However, a plate heat exchanger regenerator is restricted to low viscosities.

King Engineering is the leading manufacturer, distributor, and seller of all types of Plate Type Heat Exchangers.

Get in touch with our support team and they will guide you as per your requirements.