Spiral Wound Gasket Types

Spiral Wound Gaskets Explained - Definition, Types, and Features.

An example of a spiral wound gasket commonly seen in oil refineries, with a yellow outer ring.

An example of a spiral wound gasket commonly seen in oil refineries, with a yellow outer ring.

What is Spiral Wound Gasket?

Following are the details about Spiral Wound Gaskets. Spiral Wound Gasket Types and it's features. Kingengineering also have the custom Spiral Wound Gaskets as per your requirements.

A Spiral Wound Gasket is the most common metallic gasket used in industrial plants. A properly selected and installed spiral wound gasket can withstand high temperatures and pressures, preventing leaks throughout its intended lifespan.

A spiral wound gasket consists of three elements:

- Outer ring. Made of carbon steel, this outer ring is sometimes called the centering ring or guide ring. It’s used to center the gasket when you insert it into a bolted flange joint.

- Inner ring. The inner ring is pivotal for the gasket because it prevents windings from buckling inside the pipe. When a gasket buckles, parts of it get sucked into the pipe. From there, pieces of the gasket will typically flow through the pipeline until they get caught on something. Often, they’ll get wrapped around rotating equipment like a pump. The mess that results is known as a “bird’s nest.” Inner rings help you avoid this problem.

- Sealing element. As you might guess from the name, the sealing element creates a seal that prevents leaks. A sealing element encompasses both windings and filler material. Most spiral wound gaskets in oil and gas refineries will use a flexible graphite filler material rated for high temperatures. A flexible graphite filler also allows the gasket to be more tolerant of flange distortion and joint misalignment. Polytetrafluoroethylene (PTFE) is another common filler material. PTFE is not rated for high-temperature applications, however. Meanwhile, most winding materials in refineries will be stainless steel and monel.

Spiral Wound Gasket Markings

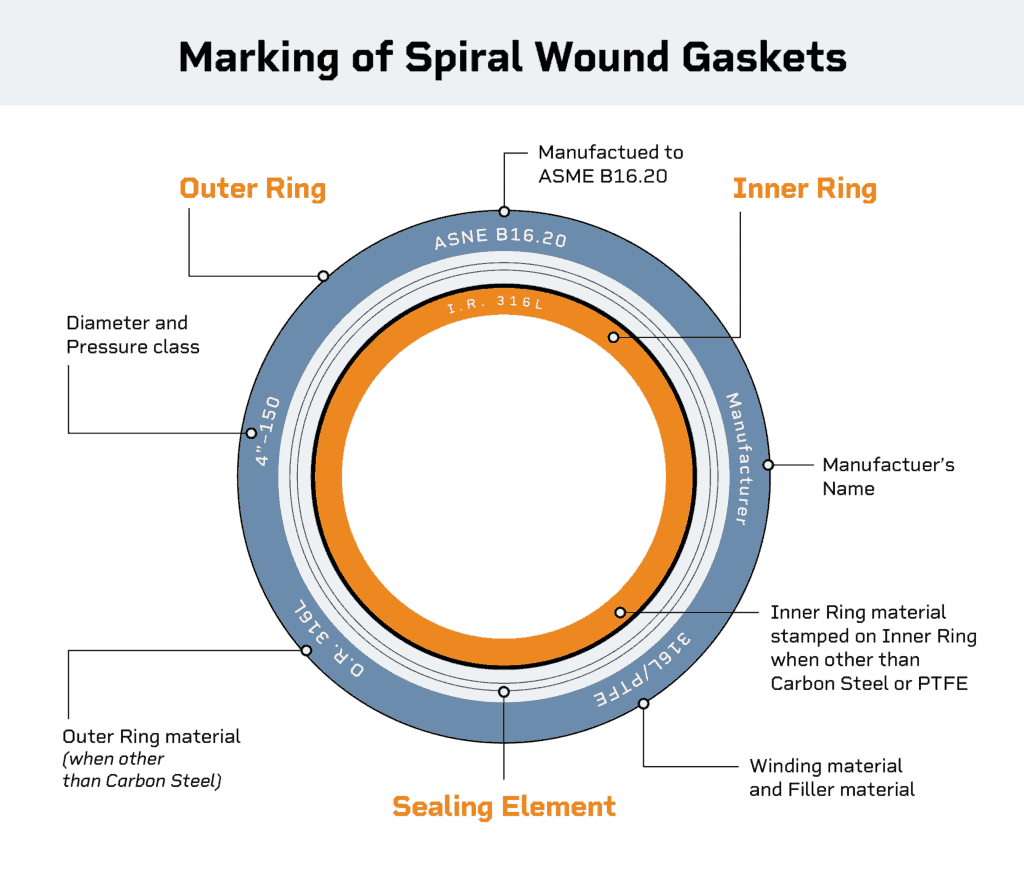

An illustration explaining the markings on a spiral wound gasket.

An illustration explaining the markings on a spiral wound gasket.

Spiral Wound Gaskets have several different markings on them. Each tells you something specific and important about the gasket itself. Starting from the top…

ASME B16.20

At the top of a spiral wound gasket, you ought to see a marking that states “ASME B16.20.” this indicates the gasket is made to the ASME B16.20 standard, which is the standard governing metallic gaskets for pipe flanges (which includes spiral wound gaskets).

Manufacturer:

First, the manufacturer’s name is usually positioned on the right-hand side of the gasket. This tells you who made the gasket.

Winding Material and Filler Material

Indicates what the gasket is made of. Gasket color also tells you a lot about these materials — more on that in a moment.

Diameter and Pressure class

These markings tell you the size of the gasket, along with the load the gasket can handle.

There are different pressure classes: 150, 300, 400, 600, 900, 1500, and 2500. Higher numbers indicate the ability to tolerate greater pressures.

Why Spiral Wound Gaskets are in use?

Spiral Wound Gaskets have been around since 1912, but they were not used regularly in industrial piping until the 1990s.

On July 12, 1989, the EPA issued a final rule banning most asbestos-containing products. That included gaskets. At the time, asbestos gaskets were used in applications under lower temperatures and pressures because they weren’t at risk for blowout under those conditions. Ring Joint Gaskets were used in high-temperature (~500+ degrees Fahrenheit) and high-pressure applications.

Spiral Wound Gaskets are incredible gaskets for both pipings (preferred gaskets in ASME B16.5 and B16.47 flanges). While the Kammprofile gasket gets a lot of attention from heat exchangers, spiral wound gaskets are also great for them.

Compressibility and recovery are what make spiral wound gaskets the best metallic gaskets for most flanges. They are now the metal gasket that has taken favor over Ring Type Joints for even high-pressure flanges including ASME B16.5 2500 series flanges.